Welcome to MORPHOTEC!

Innovation through Simulation.

Heat Transfer Simulation using FEA are to be performed, in case stationary or time-dependant temperature fields within a component / assembly group in consequence of sources of heat are of particular interest. Project examples of stationary or transient Finite-Element-Simulations of Heat Transfer performed for customers of MORPHOTEC are:

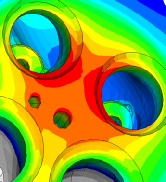

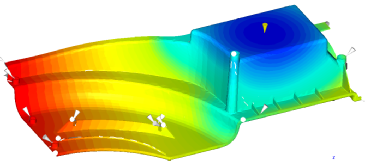

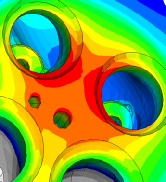

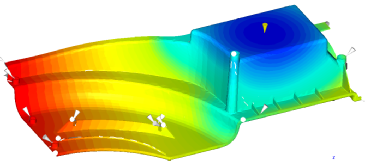

- FE-Simulation of temperature fields (stationary or transient) within combustion engines (passenger vehicle, light and heavy truck) using heat transfer coefficients and near-wall fluid temperatures being calculated by means of computational fluid dynamics.

- Layout of a liquid cooling system of injection moulds with near-wall cooling channels with the goal to reduce the cycle time of the injection moulding process.

- Conjugate heat transfer simulation of an electronic high-power resistor.

Our CAE-Serviceportfolio comprises the following fields

- Finite-Element-Simulations of heat transfer with

- stationary and non-steady state conditions

- heat flux

- radiation

- convection

- fixed temperatures or temperature profiles

- temperature-dependant material properties

- transfer of simulated temperature fields to thermomechanical strength analysis

- direct coupling of computational fluid flow analysis with heat transfer simulation

- use of heat transfer coefficients and near-wall fluid temperatures calculated by means of CFD